Lifestock, poultry, food security and climate solutions for turn-key business projects

Apers group, headquartered in Dubai, the UAE, is an international industrial business with more than 10 operating companies, spread throughout 4 countries, with over 200 employees. The Apers Group companies break down into four divisions: equipment manufacturing for poultry and lifestock farms, vegetable and fruits post harving technologies, industrial ventilation and cooling systems and equipment, turn-key agribusiness projects.

Industies & Solutions

Revolution technologies of Industry 4.0 drives to best efficiancy and results

Companies & Countries

We are all around you more then 30 years

Agrovent

Agrovent is a leading manufacturer of agricultural equipment and technology, with a focus on providing solutions for greenhouse and indoor crop production.

Allcerr

Marketing and consulting group in the agritech industry which help businesses in the agriculture and technology sectors to promote and sell their products and services effectively

ABF

A company involved in the manufacture of industrial ventilation systems specializes in designing, manufacturing, and installing ventilation systems for industrial facilities. These systems are essential for maintaining a healthy and safe work environment for employees, as well as ensuring the efficient operation of machinery and equipment

Beltechcom

Beltechkom is a Belarus company that specializes in the production and distribution of ventilation components and equipment. The company offers a wide range of products, including air handling units

About us

For more than 30 years we have been delivering world-class construction and we’ve built many lasting relationships along the way.

We’ve matured into an industry leader and trusted resource for those seeking quality, innovation and reliability when building in the World

What can us do for you?

We are ready to work on a project of any complexity, whether it’s commercial or residential

Audit & support

The agribusiness sector is an important pillar of the economy and plays a crucial role in meeting the global demand for food, feed, and fiber. The sector is highly regulated and has complex operations, which makes it challenging for businesses to stay compliant with regulations, mitigate risks, and maximize profitability. To navigate these challenges, agribusinesses require specialized audit and consulting services.

Audit services are essential for agribusinesses to ensure that their financial statements are accurate and comply with the generally accepted accounting principles (GAAP) and International Financial Reporting Standards (IFRS). Audits provide an independent and objective assessment of the financial health of a company, which helps stakeholders make informed decisions. In the agribusiness sector, audits are crucial for securing loans, attracting investors, and maintaining trust with stakeholders.

Apers Group auditors in the agribusiness sector face unique challenges such as fluctuating commodity prices, climate change, and supply chain disruptions. These challenges require auditors to have a deep understanding of the sector, including the farming, processing, and distribution of agricultural products. Auditors also need to be aware of the regulatory environment, including laws and regulations governing food safety, labor practices, and environmental standards. Consulting services are also critical for agribusinesses to optimize their operations, manage risks, and achieve their strategic objectives. Consultants in the agribusiness sector provide a range of services, including risk management, supply chain optimization, technology implementation, and sustainability strategies. Consultants help agribusinesses improve their efficiency, reduce costs, and increase profitability.

Consultants in the agribusiness sector must have specialized knowledge of the sector, including the latest trends, technologies, and best practices. They must also have a deep understanding of the local and global markets and the regulatory environment. With this knowledge, consultants can help agribusinesses identify opportunities, mitigate risks, and achieve their objectives. In conclusion, audit and consulting services are crucial for agribusinesses to ensure compliance with regulations, mitigate risks, and maximize profitability. Auditors and consultants in the agribusiness sector face unique challenges and require specialized knowledge to provide effective services. As the agribusiness sector continues to evolve, audit and consulting services will become increasingly important for companies to succeed in this dynamic and complex industry.

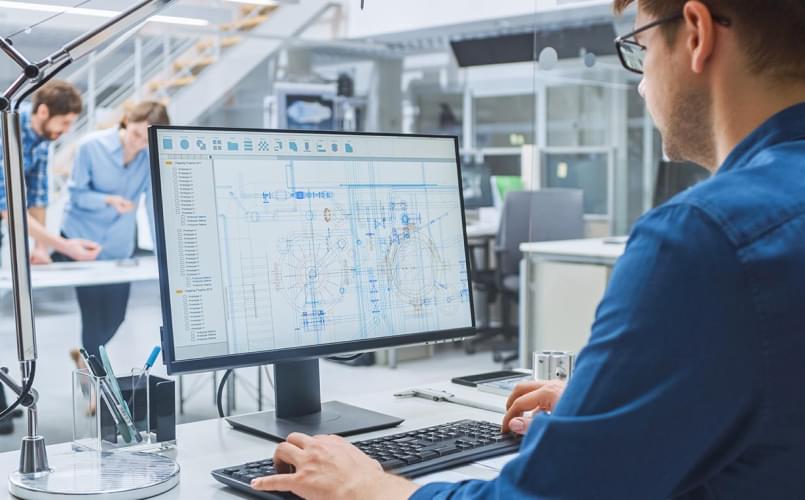

Engineering

Engineering in agribusiness refers to the application of engineering principles, techniques, and technologies to optimize agricultural processes and systems. This multidisciplinary field combines knowledge from agricultural sciences, engineering, and business to develop efficient, sustainable, and profitable solutions for the agribusiness sector. Some key areas of focus in agribusiness engineering include:

- Farm machinery and equipment design: Developing and improving agricultural machinery and tools to increase efficiency, productivity, and safety. Examples include tractors, harvesters, seeders, and irrigation systems.

- Precision agriculture: Using advanced technologies such as GPS, remote sensing, and data analytics to optimize crop management, monitor plant health, and make data-driven decisions for improving yields and reducing environmental impact.

- Agricultural robotics and automation: Designing and implementing automated systems, such as drones and robotic machinery, for tasks like planting, harvesting, and monitoring crops. These technologies help reduce labor costs and improve efficiency.

- Food processing and storage: Engineering efficient systems for processing, preserving, and packaging agricultural products to maintain their quality, safety, and shelf life. This can include the development of innovative techniques and machinery for food processing.

- Irrigation and water management: Designing efficient irrigation systems to optimize water use and reduce waste, while ensuring that crops receive the necessary water to grow. This can involve the use of sensors and remote monitoring systems for water management.

- Renewable energy in agriculture: Implementing renewable energy solutions such as solar, wind, and biomass to reduce dependence on fossil fuels and minimize greenhouse gas emissions in agricultural operations.

- Waste management and environmental sustainability: Developing strategies and technologies to minimize waste, reduce pollution, and promote sustainable practices in agriculture. This can include the management of agricultural waste, such as manure and crop residues, for biogas production or composting.

- Supply chain optimization: Leveraging data and analytics to optimize agricultural supply chains, ensuring that products are transported and delivered efficiently and sustainably.

- Farm infrastructure and planning: Designing and building farm structures, such as greenhouses, barns, and storage facilities, as well as planning farm layouts for optimal productivity and sustainability.

- Agribusiness management and economics: Applying engineering principles to the business side of agriculture, including farm management, production planning, and financial analysis.

By integrating engineering principles with agricultural knowledge and business acumen, agribusiness engineering contributes to the development of innovative solutions for the complex challenges facing the global food system.

Microclimate

Creating a favorable microclimate in livestock facilities using ventilation equipment is crucial for the health and productivity of animals. Ventilation systems play a key role in regulating temperature, humidity, and air quality within these environments. Firstly, maintaining an optimal temperature is essential for the well-being of livestock. Ventilation helps in dissipating excess heat and moisture, thereby preventing the buildup of harmful gases like ammonia and carbon dioxide. This is particularly important in densely populated facilities, where the body heat and respiration of animals can significantly alter the ambient conditions. Secondly, proper air circulation is vital for disease control. Stagnant air can harbor pathogens and increase the risk of respiratory illnesses among animals. A well-designed ventilation system ensures a continuous supply of fresh air, diluting airborne contaminants and reducing the risk of disease transmission. Moreover, humidity levels need to be carefully managed. High humidity can promote the growth of mold and bacteria, while low humidity can cause respiratory issues. Ventilation systems can be equipped with sensors to monitor and adjust the humidity levels to an appropriate range. Additionally, ventilation contributes to the comfort and stress reduction of animals. A comfortable environment can lead to better feed conversion rates, growth, and overall productivity. This is especially important in facilities such as dairy farms, where stress can directly impact milk production. In summary, ventilation equipment is a critical component in creating a suitable microclimate in livestock facilities. It ensures optimal temperature, air quality, and humidity, leading to healthier animals and more efficient operations. Regular maintenance and monitoring of these systems are essential to ensure their effectiveness and adapt to changing environmental conditions.

Equipment Installation

The installation of equipment in vegetable storage and livestock facilities and the importance of its proper configuration are key factors in preserving the quality and extending the shelf life of stored produce. The primary goal in these facilities is to maintain an environment that slows down the natural decay process while preventing the growth of pathogens. Firstly, temperature control systems are crucial. Different vegetables require specific temperature ranges for optimal storage. For instance, root vegetables like potatoes and carrots are best stored at cooler temperatures, whereas tomatoes and cucumbers prefer slightly warmer conditions. Installing programmable thermostats and efficient cooling systems allows for precise temperature management, tailored to the needs of the stored produce. Secondly, humidity control is equally important. Excess moisture can lead to mold growth and rot, while too little humidity can cause dehydration and loss of quality. Humidity control systems, often integrated with temperature controls, help maintain the ideal moisture levels in the air. This is particularly critical for leafy vegetables that are prone to wilting. In addition, proper ventilation is necessary to ensure a consistent flow of fresh air and to prevent the buildup of ethylene gas, which can accelerate ripening and spoilage. Advanced ventilation systems, equipped with sensors and automatic controls, can regulate air flow based on the specific requirements of the stored vegetables. Moreover, the installation of monitoring and control systems enables real-time tracking of environmental conditions within the storage facility. These systems can alert operators to any deviations from the ideal conditions, allowing for prompt adjustments and minimizing the risk of spoilage. Finally, the importance of proper configuration and calibration of this equipment cannot be overstated. Incorrect settings can lead to suboptimal conditions that compromise the quality of the produce. Regular maintenance and calibration of equipment ensure its accuracy and reliability. In summary, the installation and correct setup of temperature, humidity, and ventilation systems in vegetable storage facilities are essential for maintaining the quality and longevity of stored produce. These systems must be precisely configured and regularly maintained to meet the specific needs of different types of vegetables, ensuring their freshness and safety for consumption.

Launching objects

The importance of correctly configuring equipment in vegetable storage facilities and livestock complexes is a critical aspect for achieving successful business outcomes. Proper equipment settings directly impact the quality of produce and the health of livestock, which in turn affect the profitability and sustainability of these businesses. In vegetable storage facilities, the precise calibration of temperature, humidity, and ventilation systems is essential to preserve the freshness and extend the shelf life of produce. Different vegetables have specific storage requirements; for example, leafy greens require different conditions compared to root vegetables. Incorrect temperature or humidity settings can lead to spoilage or dehydration, resulting in significant losses. Therefore, the right settings not only ensure the quality of the produce but also reduce wastage, directly affecting the bottom line. Similarly, in livestock complexes, the proper configuration of ventilation, heating, and cooling systems is vital for maintaining the health and well-being of animals. Livestock are sensitive to their environment; too much heat, cold, or poor air quality can lead to stress, illness, and reduced productivity. For instance, dairy cows under stress produce less milk, and overcrowded poultry facilities with poor ventilation can experience higher disease rates. By ensuring the right environmental conditions, businesses can maximize the productivity and health of their livestock, leading to higher yields and better quality products. Furthermore, modern equipment often comes with advanced monitoring and control systems. Utilizing these technologies to their full potential through correct configuration and regular maintenance can lead to more efficient operations. Automated systems can reduce the need for manual labor and minimize human error, leading to more consistent and reliable outcomes. The integration of proper equipment settings and maintenance practices also demonstrates a commitment to sustainable and responsible business practices. This can enhance the reputation of the business, appealing to consumers and partners who value sustainability and animal welfare. In conclusion, the correct configuration of equipment in both vegetable storage facilities and livestock complexes is not just a technical necessity but a strategic business decision. It plays a pivotal role in ensuring product quality, reducing waste, enhancing animal welfare, and ultimately driving the profitability and sustainability of the business. As such, regular reviews and updates of these settings, aligned with the latest best practices and technological advancements, are essential for ongoing success.

Service

Servicing vegetable storage facilities and livestock housing is a critical aspect of agricultural operations, encompassing a range of activities designed to ensure these environments remain optimal for their respective purposes. Regular and effective service of these facilities is essential for maintaining the quality of stored produce and the health of livestock, which directly impacts the productivity and profitability of agricultural businesses. For vegetable storage facilities, servicing primarily focuses on maintaining the environmental control systems. This involves regular checks and calibration of temperature and humidity control equipment, ensuring they are functioning within the required parameters for different types of produce. Ventilation systems also need frequent maintenance to guarantee a constant supply of fresh air and prevent the accumulation of harmful gases like ethylene, which can accelerate the ripening process and lead to spoilage. In addition, pest control is a vital part of servicing vegetable storage facilities. Regular inspections and treatments are necessary to prevent infestations that can damage stored produce. Cleaning and sanitization are also crucial to prevent the growth of mold and bacteria, which can thrive in the moist, enclosed environments of storage facilities. For livestock housing, servicing involves a different set of priorities, chiefly focused on ensuring the health and comfort of animals. This includes maintaining ventilation systems to provide fresh air and control temperature and humidity levels, which are crucial for preventing respiratory problems and heat stress in animals. Regular cleaning and disinfection of these spaces are also essential to prevent the spread of diseases. Feeding and watering systems require regular maintenance to ensure they are delivering the correct quantities of food and water and are free from contaminants. Moreover, regular checks of fencing, gates, and other structural components are necessary to ensure the safety and security of the animals. Both types of facilities benefit greatly from the integration of automated monitoring systems, which can alert managers to issues like temperature fluctuations or equipment malfunctions. These systems allow for quicker responses, minimizing the risk of damage to produce or harm to livestock. Servicing also includes keeping up with the latest technological advancements and best practices in agricultural management. This might involve upgrading equipment or implementing new methodologies to improve efficiency and effectiveness. In summary, regular and thorough servicing of vegetable storage facilities and livestock housing is essential for maintaining the quality of produce and the health of animals. This service encompasses a range of activities, including equipment maintenance, pest control, cleaning, and the implementation of new technologies and practices. These activities are vital for the smooth operation and success of agricultural businesses.

Agrovent

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla quam velit, vulputate eu pharetra nec, mattis ac neque. Duis vulputate commodo lectus, ac blandit elit tincidunt id. Sed rhoncus, tortor sed eleifend tristique, tortor mauris molestie elit, et lacinia ipsum quam nec dui. Quisque nec mauris sit amet elit iaculis pretium sit amet quis magna.

Aenean velit odio, elementum in tempus ut, vehicula eu diam. Pellentesque rhoncus aliquam mattis. Ut vulputate eros sed felis sodales nec vulputate justo hendrerit. Vivamus varius pretium ligula, a aliquam odio euismod sit amet.

h3 title

- Lorem ipsum dolor sit amet, consectetur adipiscing elit.

- Nulla quam velit, vulputate eu pharetra nec, mattis ac neque.

- Duis vulputate commodo lectus, ac blandit elit tincidunt id.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit.

- Nulla quam velit, vulputate eu pharetra nec, mattis ac neque.

- Duis vulputate commodo lectus, ac blandit elit tincidunt id.

Nulla quam velit, vulputate eu pharetra nec, mattis ac neque. Duis vulputate commodo lectus, ac blandit elit tincidunt id. Sed rhoncus, tortor sed eleifend tristique, tortor mauris molestie elit, et lacinia ipsum quam nec dui.

Allcerr

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla quam velit, vulputate eu pharetra nec, mattis ac neque. Duis vulputate commodo lectus, ac blandit elit tincidunt id. Sed rhoncus, tortor sed eleifend tristique, tortor mauris molestie elit, et lacinia ipsum quam nec dui. Quisque nec mauris sit amet elit iaculis pretium sit amet quis magna.

Aenean velit odio, elementum in tempus ut, vehicula eu diam. Pellentesque rhoncus aliquam mattis. Ut vulputate eros sed felis sodales nec vulputate justo hendrerit. Vivamus varius pretium ligula, a aliquam odio euismod sit amet.

h3 title

- Lorem ipsum dolor sit amet, consectetur adipiscing elit.

- Nulla quam velit, vulputate eu pharetra nec, mattis ac neque.

- Duis vulputate commodo lectus, ac blandit elit tincidunt id.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit.

- Nulla quam velit, vulputate eu pharetra nec, mattis ac neque.

- Duis vulputate commodo lectus, ac blandit elit tincidunt id.

Nulla quam velit, vulputate eu pharetra nec, mattis ac neque. Duis vulputate commodo lectus, ac blandit elit tincidunt id. Sed rhoncus, tortor sed eleifend tristique, tortor mauris molestie elit, et lacinia ipsum quam nec dui.

ABF. Industrial ventilation equipment and air handling units

The manufacturing process of industrial ventilation systems typically involves several stages, including design, fabrication, assembly, and installation. The company's engineers and technicians work closely with clients to understand their unique ventilation requirements, such as the type of facility, the equipment used, and the size of the space

Based on these requirements, the company's design team creates detailed plans and specifications for the ventilation system. This may include selecting the appropriate materials and components, such as ductwork, fans, filters, and controls, and designing the layout of the system to maximize its effectiveness

Once the design is finalized, the fabrication process begins. The components are manufactured and assembled in-house, ensuring quality control and adherence to industry standards. The company's skilled technicians ensure that each component is assembled correctly and that the finished product meets the client's specifications.

After the fabrication and assembly processes are complete, the ventilation system is ready for installation. The company's installation team works closely with the client to ensure that the system is installed correctly and in accordance with all relevant safety regulations and building codes

Finally, the company provides ongoing maintenance and support for the ventilation system, ensuring that it continues to function efficiently and effectively over time. This may include regular inspections, cleaning, and repairs as needed

Overall, a company involved in the manufacture of industrial ventilation systems plays a critical role in ensuring the safety and productivity of industrial facilities, providing customized solutions tailored to the unique needs of each client

Beltechcom

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla quam velit, vulputate eu pharetra nec, mattis ac neque. Duis vulputate commodo lectus, ac blandit elit tincidunt id. Sed rhoncus, tortor sed eleifend tristique, tortor mauris molestie elit, et lacinia ipsum quam nec dui. Quisque nec mauris sit amet elit iaculis pretium sit amet quis magna.

Aenean velit odio, elementum in tempus ut, vehicula eu diam. Pellentesque rhoncus aliquam mattis. Ut vulputate eros sed felis sodales nec vulputate justo hendrerit. Vivamus varius pretium ligula, a aliquam odio euismod sit amet.

h3 title

- Lorem ipsum dolor sit amet, consectetur adipiscing elit.

- Nulla quam velit, vulputate eu pharetra nec, mattis ac neque.

- Duis vulputate commodo lectus, ac blandit elit tincidunt id.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit.

- Nulla quam velit, vulputate eu pharetra nec, mattis ac neque.

- Duis vulputate commodo lectus, ac blandit elit tincidunt id.

Nulla quam velit, vulputate eu pharetra nec, mattis ac neque. Duis vulputate commodo lectus, ac blandit elit tincidunt id. Sed rhoncus, tortor sed eleifend tristique, tortor mauris molestie elit, et lacinia ipsum quam nec dui.

About us

h3 Title

title name

Lorem ipsum dolor

title name

Lorem ipsum dolor

title name

Lorem ipsum dolor

title name

Lorem ipsum dolor

title name

Lorem ipsum dolor

title name

Lorem ipsum dolorh3 Title window

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla quam velit, vulputate eu pharetra nec, mattis ac neque. Duis vulputate commodo lectus, ac blandit elit tincidunt id. Sed rhoncus, tortor sed eleifend tristique, tortor mauris molestie elit, et lacinia ipsum quam nec dui. Quisque nec mauris sit amet elit iaculis pretium sit amet quis magna.

Aenean velit odio, elementum in tempus ut, vehicula eu diam. Pellentesque rhoncus aliquam mattis. Ut vulputate eros sed felis sodales nec vulputate justo hendrerit. Vivamus varius pretium ligula, a aliquam odio euismod sit amet.

h3 title

- Lorem ipsum dolor sit amet, consectetur adipiscing elit.

- Nulla quam velit, vulputate eu pharetra nec, mattis ac neque.

- Duis vulputate commodo lectus, ac blandit elit tincidunt id.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit.

- Nulla quam velit, vulputate eu pharetra nec, mattis ac neque.

- Duis vulputate commodo lectus, ac blandit elit tincidunt id.

Nulla quam velit, vulputate eu pharetra nec, mattis ac neque. Duis vulputate commodo lectus, ac blandit elit tincidunt id. Sed rhoncus, tortor sed eleifend tristique, tortor mauris molestie elit, et lacinia ipsum quam nec dui.